About Project FORCE

The UK Government Department for Business Energy and Industrial Strategy (BEIS) has tasked Frazer-Nash and our partner organisations with delivering an Advanced Manufacturing and Materials research and innovation Project.

The project consists of three work packages focussed on developing structural integrity assessment methods with an aim to reduce the blockers for the wide-scale use of power beam welding techniques in the nuclear industry.

Highlights

An insight into our work within Project FORCE to help deliver Advanced Manufacturing and Materials capability throughout the nuclear innovation program

Weld Residual Stress Modelling

Characterising EB and LB weldments and developing modelling approach to predict weld residual stresses accurately and efficiently.

Probabilistic Methods for Structural Integrity

Development a probabilistic framework for how the variation in material properties and welding residual stresses can be accounted for in structural integrity assessments.

Fracture in Power Beam Welds

Measuring and predicting the fracture behaviour of power beam weldments in the presence of weld residual stresses.

Benefits

Project FORCE is focussed on reducing the blockers for the wide-scale use of power beam welding techniques in the nuclear industry. The adoption of power beam welding by the nuclear industry could significantly cut manufacturing costs, particularly with the move to modularisation where systems are assembled within a factory environment.

Reduce Cost

Share Knowledge

Improve Assurance

Collaborate

Application Led

Validate

Helping to remove the blockers

from power beam welding

in nuclear new build

Our Work

Motivation for Project Force

Welding metallic components is a core technology across all nuclear reactor designs. There are a range of welding techniques and each results in complex microstructures in the vicinity of the weld. Understanding the effect of welding parameters on material properties and residual stresses is of paramount importance for structural integrity in the design and operation of nuclear plant.

Nuclear Innovation Programme

The Nuclear Innovation Programme is an integrated 5 year programme of research and innovation funded by BEIS to further the UK's civil nuclear power objectives as set out in the Nuclear Sector Deal. Advanced Manufacturing and Materials is one of the six key research areas that form the Nuclear Innovation Programme.

Nuclear Structural Materials

The nuclear structural materials R&D theme is focussed on developing materials performance data and fundamental understanding of materials and related manufacturing processes suitable for use in the next generation of high value components for SMRs and Gen IV reactor systems.

Benefits of Power Beam Welding

Electron beam (EB) and laser beam (LB) welding techniques have great potential for future nuclear reactors. Benefits over contemporary techniques include: faster process time, smaller heat affected zone, and potentially favourable welding residual stresses. A greater understanding of power beam techniques is required for their wide-scale adoption, which includes developing validated modelling approaches that allow complex materials effects to be predicted and optimised.

Weld Residual Stress Modelling

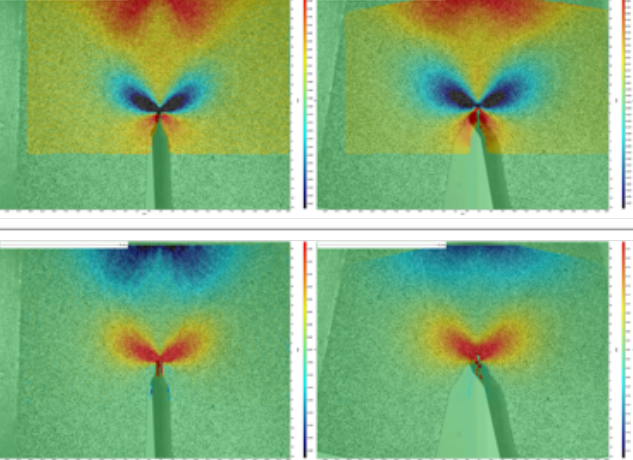

Understanding welding residual stresses is important for assuring the structural integrity of nuclear components. Technology improvements will lead to increased confidence in life and potentially reduced inspection requirements. There are a number of failure mechanisms which need to be considered in nuclear components and residual stress can influence the damage development of these mechanisms. An additional benefit of the finite element weld modelling technology is the ability to predict weld distortion, which can improve manufacturability and reduce fit-up stress.

Probabilistic Methods for Structural Integrity

There is considerable interest in probabilistic assessment methods in the nuclear industry. This field of work is particularly pertinent to SMRs, but is also of interest to designers, manufacturers and operators of other nuclear reactor designs. For designers and manufacturers it allows them to adopt a Design for Reliability approach, which helps them to focus on the key areas of the design. For operators, probabilistic methods provide insight beyond deterministic assessment and can contribute to life extension.

Fracture in Power Beam Welds

Fracture is one of the principal mechanisms considered in structural integrity assessments. As power beam techniques are introduced to the nuclear industry it is important that material properties of welds, such as fracture toughness, can be predicted accurately. The development of advanced modelling approaches with experimental validation will lead to improved structural integrity methods that can account for the effects of residual stress, loss of constraint and environmental effects.

Downloads

Case Studies

Nuclear Innovation UK Conference - July 2019

News

Frazer Nash secures contract to support the government s-nuclear research and development programme

Collaboration and Connection; the focus of the South West Nuclear Conference

Contact Us

Contact Name

Andrew Moffat

Address

Stonebridge House, Dorking Business Park, Dorking, Surrey, RH4 1HJ, UK